SHED FEATURES

< BACK TO THE YARD

We add a durable aluminum plate to the threshold of every Cook building to provide additional protection against daily wear and tear.

ALUMINUM THRESHOLD

Our 2 x 4 wall studs are placed 24″ on center with Double Studs put where the siding meets. This technique provides a larger nailing surface and prevents separation and gaps at the siding seams.

DOUBLE STUDS

We use Storm Chains to prevent potential damage caused by high winds.

STORM CHAINS

FLOOR DECKING

Contact rated floor joists are placed 16″ on center and covered with 5/8″ LP ProStruct flooring to provide added strength. This decking prevents the floor system from sagging under the weight of heavy possessions.

All of the shingles used on Cook buildings are grade “A” shingles that carry a 30-year manufacturer’s limited warranty.

DRIP EDGE

7/16″ oriented strand board (OSB) is used for roof decking because it is manufactured with heat resistant glues that prevent delamination and warping.

ROOF DECKING

Our locking door handle provides enhanced security for your items and works despite the possible settling of your Cook shed.

LOCKING DOOR HANDLE

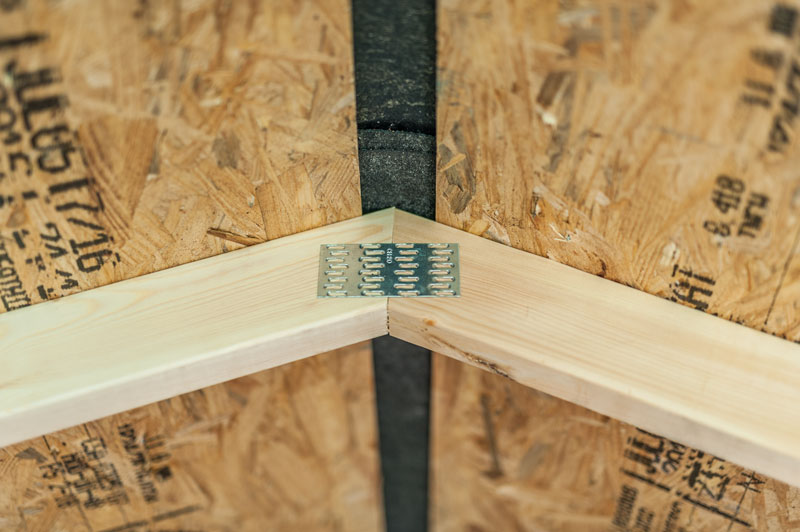

2×4 trusses are placed 24″ on center and gusseted to add strength to the roof system to keep it from sagging from the weight of snow and ice.

GUSSETED TRUSSES

SHALLOW GROOVE SIDING

Our exclusive 19/32″ LP Smartside Shallow Groove Siding enhances the aesthetic value of Cook buildings while retaining strength and integrity. Using Shallow Groove Siding significantly reduces the possibility of delamination.

Two adjustable tension rods are installed on every door to prevent warping as the shed is exposed to the elements over the years.

ADJUSTABLE TENSION RODS

HEAVY DUTY 6-INCH DOOR HINGES

Every door is installed with three heavy duty 6″ zinc plated hinges to provide maximum strength and durability.

All of the shingles used on Cook buildings are grade “A” shingles that carry a 30-year manufacturer’s limited warranty.

30-YEAR ARCHITECTURAL SHINGLES

PRESSURE TREATED LUMBER

We use of the highest rated lumber for direct ground contact for the entire floor system including skids, floor joists, and decking. This enables Cook to extend a lifetime warranty against decay or termite damage on every own of our sheds.

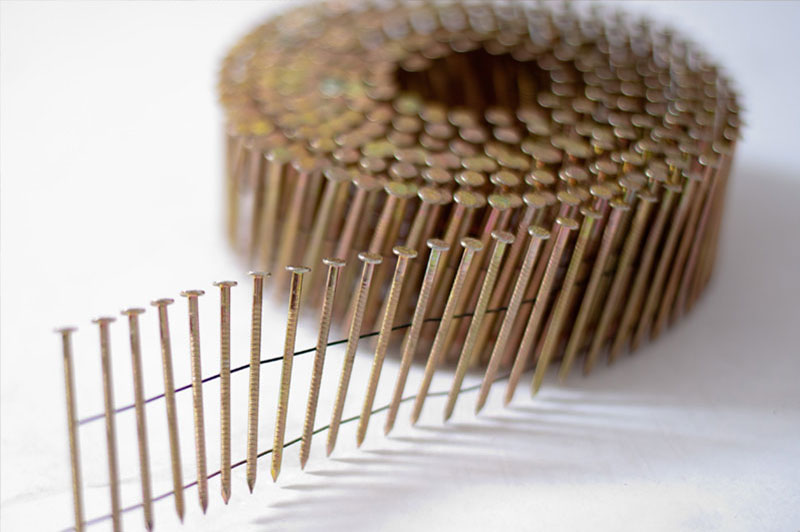

Ring shank coated nails are used throughout the sidewall construction of our shed. These fasteners provide maximum holding strength against swelling and contracting caused by changes in weather or humidity.

FASTENERS

NOTCHED WALL PLATES

The 2 x 8 top wall plates (in barns and lofted barn models) are notched to allow the siding to be placed into the framing, rather than nailing the siding to the sidewall frame to increase the strength and durability of the building and create a better seal against the effects of weather.

Venting the roof at its peak along the ridge provides superior ventilation. This technique helps prevent damage to shingles and your stored property that may be caused by excessive heat.

VENTED RIDGE

The 4 x 6 pressure treated floor skids are notched so the floor joists can be recessed into the skid. This provides added strength and durability and allows for movement without damage. (Note: 8 foot wide buildings have 2 skids and 10 and 12 foot wide buildings have 4 skids each).

NOTCHED FLOOR SKIDS

PULLING BLOCKS

Pulling blocks are installed with holes drilled at each end of the centermost skids. These blocks help prevent damage if a building needs to be moved.

TAKE A LOOK INSIDE >GARAGEVIRTUAL TOUR360° View

TAKE A LOOK INSIDE >GARAGEVIRTUAL TOUR360° View

TAKE A LOOK INSIDE >GARAGEVIRTUAL TOUR360° View

TAKE A LOOK INSIDE >GARAGEVIRTUAL TOUR360° View

TAKE A LOOK INSIDE >GARAGEVIRTUAL TOUR360° View

TAKE A LOOK INSIDE >GARAGEVIRTUAL TOUR360° View

TAKE A LOOK INSIDE >

TAKE A LOOK INSIDE > GARAGEVIRTUAL TOUR360° View

GARAGEVIRTUAL TOUR360° View

TAKE A LOOK INSIDE >GARAGEVIRTUAL TOUR360° View

TAKE A LOOK INSIDE >GARAGEVIRTUAL TOUR360° View

TAKE A LOOK INSIDE >GARAGEVIRTUAL TOUR360° View

TAKE A LOOK INSIDE >GARAGEVIRTUAL TOUR360° View

TAKE A LOOK INSIDE >GARAGEVIRTUAL TOUR360° View

TAKE A LOOK INSIDE >GARAGEVIRTUAL TOUR360° View

TAKE A LOOK INSIDE >

TAKE A LOOK INSIDE > GARAGEVIRTUAL TOUR360° View

GARAGEVIRTUAL TOUR360° View

TAKE A LOOK INSIDE >GARAGEVIRTUAL TOUR360° View

TAKE A LOOK INSIDE >GARAGEVIRTUAL TOUR360° View

SHED FEATURES< BACK TO THE YARD

SHED FEATURES< BACK TO THE YARD We add a durable aluminum plate to the threshold of every Cook building to provide additional protection against daily wear and tear.

We add a durable aluminum plate to the threshold of every Cook building to provide additional protection against daily wear and tear. ALUMINUM THRESHOLD

ALUMINUM THRESHOLD Our 2 x 4 wall studs are placed 24″ on center with Double Studs put where the siding meets. This technique provides a larger nailing surface and prevents separation and gaps at the siding seams.

Our 2 x 4 wall studs are placed 24″ on center with Double Studs put where the siding meets. This technique provides a larger nailing surface and prevents separation and gaps at the siding seams. DOUBLE STUDS

DOUBLE STUDS

We use Storm Chains to prevent potential damage caused by high winds.STORM CHAINS

We use Storm Chains to prevent potential damage caused by high winds.STORM CHAINS

FLOOR DECKINGContact rated floor joists are placed 16″ on center and covered with 5/8″ LP ProStruct flooring to provide added strength. This decking prevents the floor system from sagging under the weight of heavy possessions.

FLOOR DECKINGContact rated floor joists are placed 16″ on center and covered with 5/8″ LP ProStruct flooring to provide added strength. This decking prevents the floor system from sagging under the weight of heavy possessions.

All of the shingles used on Cook buildings are grade “A” shingles that carry a 30-year manufacturer’s limited warranty.DRIP EDGE

All of the shingles used on Cook buildings are grade “A” shingles that carry a 30-year manufacturer’s limited warranty.DRIP EDGE

7/16″ oriented strand board (OSB) is used for roof decking because it is manufactured with heat resistant glues that prevent delamination and warping.ROOF DECKING

7/16″ oriented strand board (OSB) is used for roof decking because it is manufactured with heat resistant glues that prevent delamination and warping.ROOF DECKING

Our locking door handle provides enhanced security for your items and works despite the possible settling of your Cook shed.LOCKING DOOR HANDLE

Our locking door handle provides enhanced security for your items and works despite the possible settling of your Cook shed.LOCKING DOOR HANDLE

2×4 trusses are placed 24″ on center and gusseted to add strength to the roof system to keep it from sagging from the weight of snow and ice.GUSSETED TRUSSES

2×4 trusses are placed 24″ on center and gusseted to add strength to the roof system to keep it from sagging from the weight of snow and ice.GUSSETED TRUSSES

SHALLOW GROOVE SIDINGOur exclusive 19/32″ LP Smartside Shallow Groove Siding enhances the aesthetic value of Cook buildings while retaining strength and integrity. Using Shallow Groove Siding significantly reduces the possibility of delamination.

SHALLOW GROOVE SIDINGOur exclusive 19/32″ LP Smartside Shallow Groove Siding enhances the aesthetic value of Cook buildings while retaining strength and integrity. Using Shallow Groove Siding significantly reduces the possibility of delamination.

Two adjustable tension rods are installed on every door to prevent warping as the shed is exposed to the elements over the years.ADJUSTABLE TENSION RODS

Two adjustable tension rods are installed on every door to prevent warping as the shed is exposed to the elements over the years.ADJUSTABLE TENSION RODS

HEAVY DUTY 6-INCH DOOR HINGESEvery door is installed with three heavy duty 6″ zinc plated hinges to provide maximum strength and durability.

HEAVY DUTY 6-INCH DOOR HINGESEvery door is installed with three heavy duty 6″ zinc plated hinges to provide maximum strength and durability.

All of the shingles used on Cook buildings are grade “A” shingles that carry a 30-year manufacturer’s limited warranty.30-YEAR ARCHITECTURAL SHINGLES

All of the shingles used on Cook buildings are grade “A” shingles that carry a 30-year manufacturer’s limited warranty.30-YEAR ARCHITECTURAL SHINGLES

PRESSURE TREATED LUMBERWe use of the highest rated lumber for direct ground contact for the entire floor system including skids, floor joists, and decking. This enables Cook to extend a lifetime warranty against decay or termite damage on every own of our sheds.

PRESSURE TREATED LUMBERWe use of the highest rated lumber for direct ground contact for the entire floor system including skids, floor joists, and decking. This enables Cook to extend a lifetime warranty against decay or termite damage on every own of our sheds. Ring shank coated nails are used throughout the sidewall construction of our shed. These fasteners provide maximum holding strength against swelling and contracting caused by changes in weather or humidity.

Ring shank coated nails are used throughout the sidewall construction of our shed. These fasteners provide maximum holding strength against swelling and contracting caused by changes in weather or humidity. FASTENERS

FASTENERS

NOTCHED WALL PLATESThe 2 x 8 top wall plates (in barns and lofted barn models) are notched to allow the siding to be placed into the framing, rather than nailing the siding to the sidewall frame to increase the strength and durability of the building and create a better seal against the effects of weather.

NOTCHED WALL PLATESThe 2 x 8 top wall plates (in barns and lofted barn models) are notched to allow the siding to be placed into the framing, rather than nailing the siding to the sidewall frame to increase the strength and durability of the building and create a better seal against the effects of weather. Venting the roof at its peak along the ridge provides superior ventilation. This technique helps prevent damage to shingles and your stored property that may be caused by excessive heat.

Venting the roof at its peak along the ridge provides superior ventilation. This technique helps prevent damage to shingles and your stored property that may be caused by excessive heat. VENTED RIDGEThe 4 x 6 pressure treated floor skids are notched so the floor joists can be recessed into the skid. This provides added strength and durability and allows for movement without damage. (Note: 8 foot wide buildings have 2 skids and 10 and 12 foot wide buildings have 4 skids each).

VENTED RIDGEThe 4 x 6 pressure treated floor skids are notched so the floor joists can be recessed into the skid. This provides added strength and durability and allows for movement without damage. (Note: 8 foot wide buildings have 2 skids and 10 and 12 foot wide buildings have 4 skids each).

NOTCHED FLOOR SKIDS

NOTCHED FLOOR SKIDS

PULLING BLOCKSPulling blocks are installed with holes drilled at each end of the centermost skids. These blocks help prevent damage if a building needs to be moved.

PULLING BLOCKSPulling blocks are installed with holes drilled at each end of the centermost skids. These blocks help prevent damage if a building needs to be moved. GARAGE< BACK TO THE YARD

GARAGE< BACK TO THE YARD

VIEW SHED FEATURES >

VIEW SHED FEATURES >

Designed by Innovations Branding House

Designed by Innovations Branding House